Products

API 7-1 Casing Chikamu chekugaya chishandiso

Product profile

Chikamu chigayo imhando yecasing hwindo rekuvhura chishandiso icho chinosanganisa casing kucheka uye milling mabasa.Chigayo chechikamu chinopinda mubhokisi pamwe neBHA, uye chinocheka casing panzvimbo yakatarwa kutanga.Mushure mekunge casing yagurwa zvachose, Ichagayiwa zvakananga kubva panzvimbo iyi.Mushure mekusvika kune imwe kudzika, iyo casing hwindo rekuvhura basa rinopedzwa.chikamu chigayo chine zvakanakira chimiro chakareruka, kushanda kuri nyore kuita kuti ive inoshanda kwazvo casing yekuvhura hwindo chishandiso.

Zvichakadaro, chikamu chegayo chinogona kusvina uye kupinza simende mukushanda kwekusiya, izvo zvinogona kuita kuti simende ibatane zvakananga nekuumbwa kwechinhambwe chakareba mukati me360 madhigirii.Simende inogona kupinda mudura zvichienderana neporosity iripo uye kutsemuka kwekuumbwa, uye iyo plugging effect iri nani kupfuura iyo yekusvina simende mushure mekuputika.

Kushanda musimboti

Mushure mechikamu cheguyo chadzikiswa kunzvimbo yakatarwa mubhokisi pamwe chete neBHA, tanga tafura inotenderera, vhura pombi, piston iri muchishandiso inosundirwa pasi nekumanikidza, koni yepasi yepiston inosundira mashizha ekucheka kuvhurika uye kugadzirisa. gomba rakashama.Apo mashizha ekucheka akazaruka kusvika pahupamhi hwepamusoro, gomba rakazaruka kugadzirisa rinopera.Pasi pepombi inoenderera mberi, blade inogona kuvhurwa uye kudzorera gomba zvakananga.Mushure mekunge pombi yamiswa, piston inogadziriswazve pasi pechiito chechirimo uye mashizha ekucheka anozodzoserwa otomatiki.

Product features

(1) Mechanical dhizaini, chimiro chakareruka uye kushanda kuri nyore

(2) Kudzika kwekutanga-up pressure uye simba guru rekutsigira blade rinobatsira pakucheka casing;

(3) Yakakwira simba chitubu dhizaini inobatsira kudzoreredza otomatiki mucheki mushure mekucheka;

(4) Dhizaini yekumisa block uye pini inobatsira kumanikidza kudzoreredza chishandiso;

(5) Iyo blade ine yakakura yekuwedzera uye inogona kuiswa kune imwechete casing ine akasiyana madziro ukobvu;

(6) Iyo blade inogadzirwa nemhando yepamusoro tungsten carbide uye Bake hughes yakafanana welding process, ine yakakwirira yekucheka inoshanda uye hupenyu hurefu hwebasa.

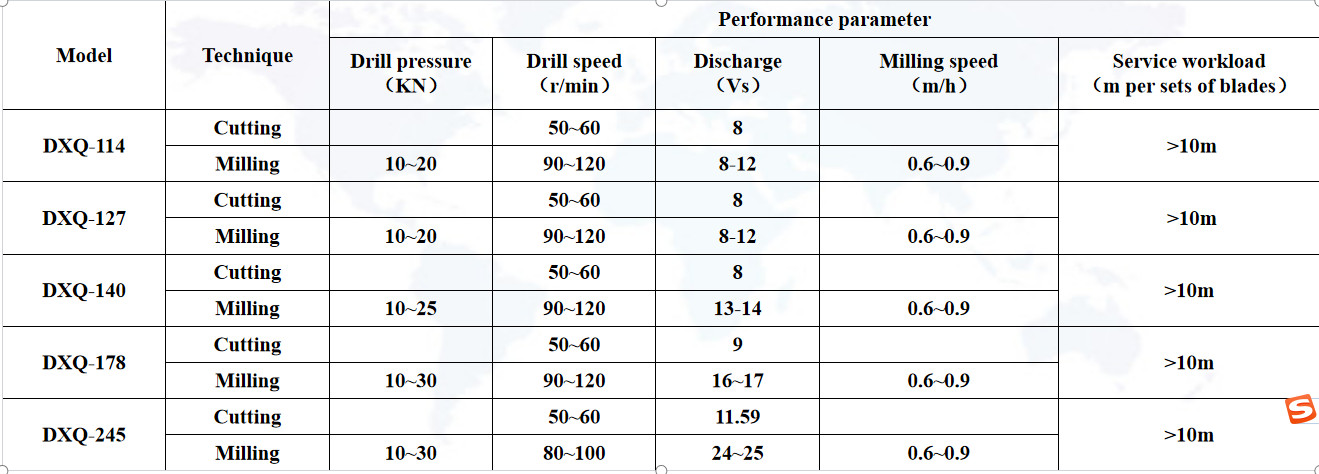

Chikamu chigayo-Size tafura

Matching maturusi - High class taper mill

Maturusi ekugaya ese akagadzirwa emhando yepamusoro tungsten carbide alloy uye Baker Hughes yakafanana welding tekinoroji.Chinangwa cheiyi nhevedzano yezvigayo ndechekudzoreredza zvachose kusarudzwa kwezvinhu, dhizaini dhizaini uye welding process yeBaker Hughes, kuitira kuti uwane iyo yakafanana chigadzirwa mhando yeBaker Hughes.

2.High class tap mill profile

inogona kuburitsa high class taper chigayo nekunze kwedhayamita 76 mm kusvika 445 mm.Iyo yepamusoro-mhando alloy simbi inoshandiswa semuviri mukuru, ichibvumira kugadziriswa kwemakomba makuru emvura kuti ive nechokwadi chekubuda kwakanaka kwemarara ekugaya.Panguva imwecheteyo, maererano nezvinodiwa chaizvo zvevatengi, chimiro chechigadzirwa chinogona kugadzirwa kuti chiwane kuita kwakanakisa kwekushandisa.

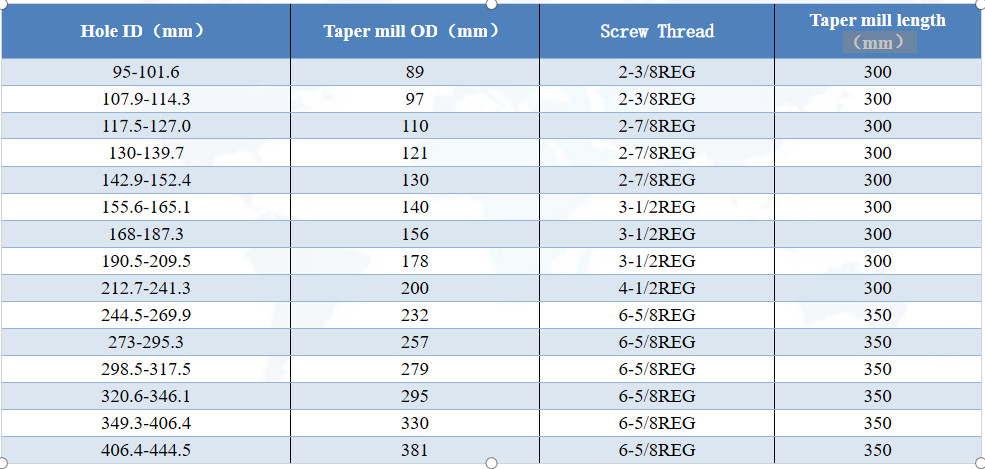

3.Taper mill-Size tafura

Chigadzirwa chimiro

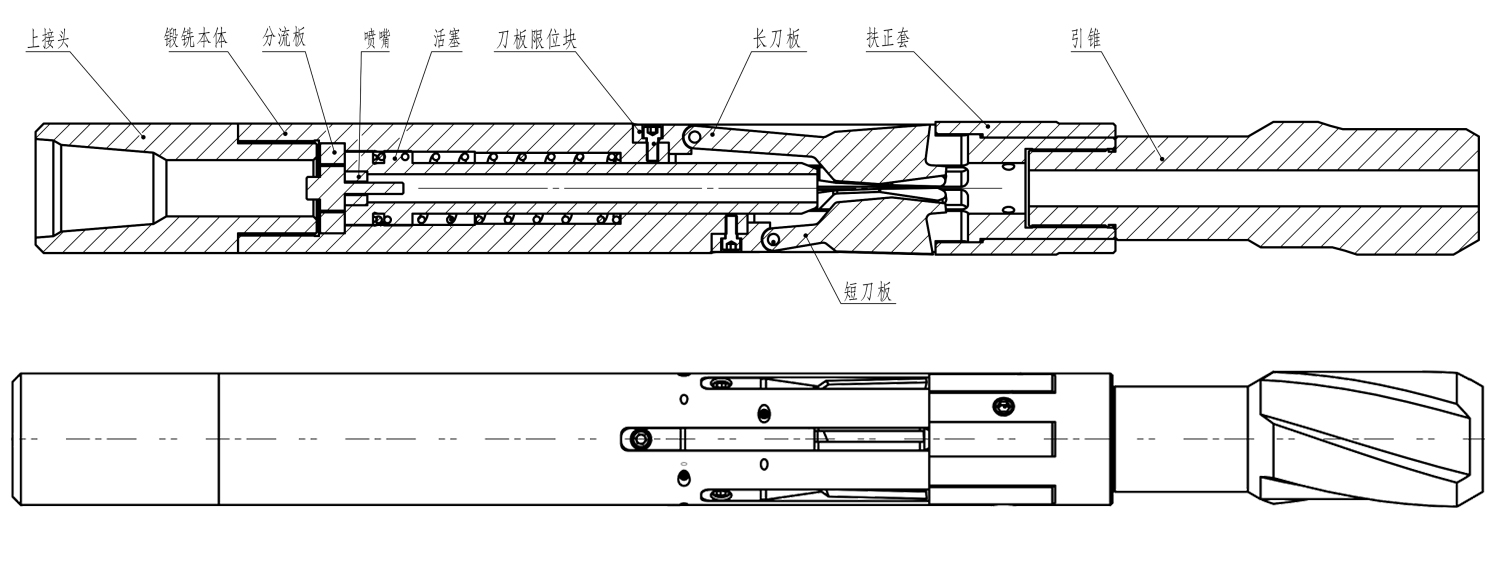

1. Chikamu chechigayo chinonyanya kusanganisira zvikamu zvinotevera: chikwata chepamusoro, muviri mukuru, piston, nozzle, mashizha ekucheka uye cone yekufambisa, nezvimwewo.

III.Technical zvakanakira Petrozhr chikamu chigayo

1.Yakagadzirwa nemhando yepamusoro tungsten carbide

Iyo chikamu chechigayo blades inogadzirwa nekambani yedu ine zvinotevera zvakanakira:

(1) Kugaya nekucheka mashandiro anokurumidza kupfuura mashizha akajairwa;

(2) Deredza kudhirowa kunodiwa pakucheka;

(3) Mavanga emazino akaenzana uye hapana nhanho inogadzirwa;

(4) Marara anogadzirwa akawedzera kufanana;

(5) Kuoma kwezvinhu zvakasvibirira kwakakwira uye chimiro chinonzwisisika.Kana ichishanda, kucheka simbi pane kukuya simbi.

2.Kuongorora kwakasimba kwezvinhu

Iyo tungsten carbide yakasarudzwa nekambani yedu inotumirwa kune inyanzvi yekuongorora agency kuti iongororwe mushure mekunge batch yega yega yasvika.Kuve nechokwadi chekuti kuoma kwealloy uye zvimwe zviratidzo zvinosangana nezvinodiwa zvekugadzira kambani.

3. Yakakwana welding process

Isu tinoshandisa aimbove Baker Hughes mukuru welder uye tinosarudza iwo maturusi ewelding nezvimwe zvekubatsira mumusangano weBaker Hughes kuti tizive kudhindwa kwehunyanzvi hweBecker welding mukuita nemidziyo.

Kuti tideredze deformation yezvishandiso nekuda kwekuchinja kwekupisa kusati kwasvika uye mushure mewelding, isu tinomisa welding insulation system kuti ive nechokwadi chekugadzikana kwechigadzirwa geometry uye kushanda nesimba.

IV.Section mill operation procedure

Kugadzirira Wellhole:

1. Gadzirisa bhokisi.Gadzirisa downhole casing ne taper mill kana casing shaper.

2. Zvakanaka Kuchenesa.Geza mafuta asina kukora kana zvimwe zvinwiwa kubva mutsime nemvura yakachena.

3. Kukwesha casing kana tsime.Kukwesha kwepombi uye kukukurwa kuchaitwa neyakajairwa scraper uye dhayamita yekukukurwa kusvika pamamita makumi maviri pazasi pechikamu chekugaya.

4. Gadzirira mvura yekugaya.Zvimiro zvaro zvakasiyana-siyana zvinogona kuve nechokwadi chakagadzikana kutakura kugona kumarara esimbi.

Ground test:

1. Edza kuvimbika kwezvishandiso;

2. Kuchinja kwepombi yepombi kunoedzwa apo mashizha ekucheka anovhurwa, izvo zvinopa hwaro hwekutonga kana iyo downhole casing yakagurwa zvachose.

Sarudzo yechinzvimbo cheMilling:

1. Simende iri kunze kwechikamu chekugaya casing inofanira kunge yakanyatso simende.

2. Dzivisa nzvimbo iyo casing ine dislocation uye deformation.Kana pane chinzvimbo chakadaro, kushanda kunofanira kuitwa 30-40m pamusoro pechinzvimbo.Uye nzvimbo yekutanga yekucheka kushanda ichave 1-3m pamusoro pekubatana kwepedyo.

3. Homwe inofanira kuchengetwa pasi pemugodhi.Kazhinji, kureba kwehomwe kunofanirwa kunge kwakakura kupfuura 100m.

Cutting casing:

① Mushure mekubatanidza chishandiso muBHA uye uchidzika pasi kune chikamu chechigayo chinzvimbo, tanga tafura inotenderera kuti uone iyo casing coupling chinzvimbo zvinoenderana necasing (logging) rekodhi, uye dzikisa chishandiso kusvika 1-3m pamusoro peiyo padhuze coupling uye brake. .

② Tanga tafura inotenderera kutanga, wedzera kukurumidza kutenderera kusvika 50-60r / min, tanga pombi, zvishoma nezvishoma kuwedzera kutama, kuitira kuti pombi iwedzere.Panguva ino, simba repombi rinowedzera kubva kudiki kusvika kune guru, zvishoma nezvishoma richiwedzera kusvika 10-12mpa.

③ Ramba uchicheka casing ye20-45min.Apo pombi yepombi inodonha kamwe kamwe ne 2-5mpa, casing inogurwa.Kuti uite kuti muviri wekucheka uvhure zvizere, chengetedza nzvimbo yekucheka panzvimbo iyi ye30min mushure mekucheka, uye zvishoma nezvishoma kuwedzera kusimuka kuti uve nechokwadi chekuumbwa kwakazara kwekuputsika.

Milling casing:

Iyo WOB inogona kuwedzerwa zvishoma nezvishoma mushure mekunge casing yagurwa.iyo inodzorwa pakati pe10-25kn, iyo inotenderera inomhanya inowedzerwa kusvika 80-120r / min, uye pombi yekumanikidza inodzorwa mukati me10MPa kuve nechokwadi chekuti kutenderera kunotenderera kunogona kutakura marara esimbi.Kana chikamu chega chega chiri chinenge 0.5m, chinogona kudhonzwa 1m kune imwe reming uye kutenderera, kuitira kuti marara esimbi anogayiwa kubva muchikamu adzoke zvakanaka kuburikidza neanobvisa.Mushure me 1-2 cycle cycles, chera mukati zvakare kuti uenderere mberi nekugadzira uye kugaya.

[Mukuita, zvinodikanwa kunyatso gadzirisa kuita kwematope uchiwedzera kutamiswa;panguva imwe chete, fambisa zvakanaka chishandiso chekuchera uye gadzirisa kutenderera kuti machipisi esimbi adzoke zvizere uye kudzivirira kuunganidzwa kwemarara]

Kamuri 703 Chivakwa B, Greenland pakati, Hi-tech yekuvandudza zone Xi'an, China

Kamuri 703 Chivakwa B, Greenland pakati, Hi-tech yekuvandudza zone Xi'an, China 86-13609153141

86-13609153141